Optimize Your Fibre Optic Efficiency: Comprehending Optical Fiber Diameter Analyser Innovation

The performance of fiber optic systems is seriously influenced by the precision of their size, an element usually neglected in the quest of optimal signal honesty. Comprehending the innovation behind optical fibre size analysers exposes the elaborate equilibrium in between measurement precision and manufacturing quality. These tools not just enhance compliance with market requirements yet also give real-time insights that can preemptively address possible problems. The ramifications of their usage prolong past simple dimension; they can basically modify the landscape of fiber optic performance. What aspects should one consider to harness their complete capacity?

Relevance of Optical Fiber Diameter

The size of optical fiber plays a crucial function in establishing the performance and performance of communication systems. It affects numerous vital specifications, consisting of the setting of light propagation, depletion, and bandwidth ability. Bigger diameters typically enable numerous light modes, helping with greater data transmission prices. On the other hand, smaller sizes tend to sustain less settings, which can boost signal clearness and reduce crosstalk.

Furthermore, recognizing the size's implications can cause cost savings by lowering the need for signal amplification and repeaters in comprehensive networks (optical fibre diameter analyser). To conclude, the importance of optical fibre size can not be overemphasized, as it directly affects the general effectiveness and dependability of contemporary interaction systems

Exactly How Diameter Influences Signal Quality

Signal high quality in optical fibre systems pivots dramatically on the size of the fiber. The size affects a number of crucial specifications, consisting of attenuation, transmission capacity, and modal dispersion. A smaller sized size can bring about higher depletion rates, causing signal loss as light travels via the fibre. This attenuation can endanger the integrity of the transmitted information, resulting in a decrease in signal quality, especially over cross countries.

Conversely, bigger sizes typically permit for improved light capture and lowered modal diffusion, enhancing signal quality. In multimode fibres, a larger core size can sustain several light settings, yet it may likewise present intermodal dispersion, which can deteriorate signal top quality. Choosing the optimum fibre size is essential for achieving the preferred efficiency in particular applications.

Furthermore, the communication in between the fiber diameter and the wavelength of the light made use of plays an important role in determining the reliable transmission distance and overall signal honesty. Recognizing just how fibre diameter influences signal high quality is vital for network developers and engineers making every effort to maximize optical fibre systems for trusted, high-speed data transmission.

Review of Diameter Analyser Modern Technology

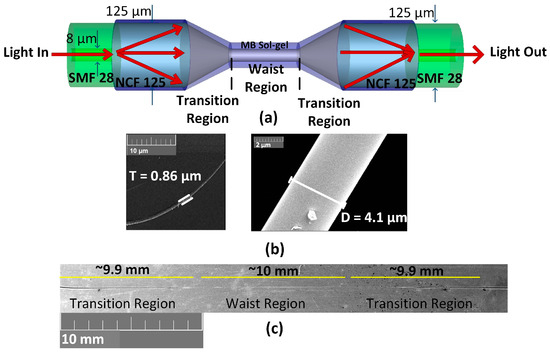

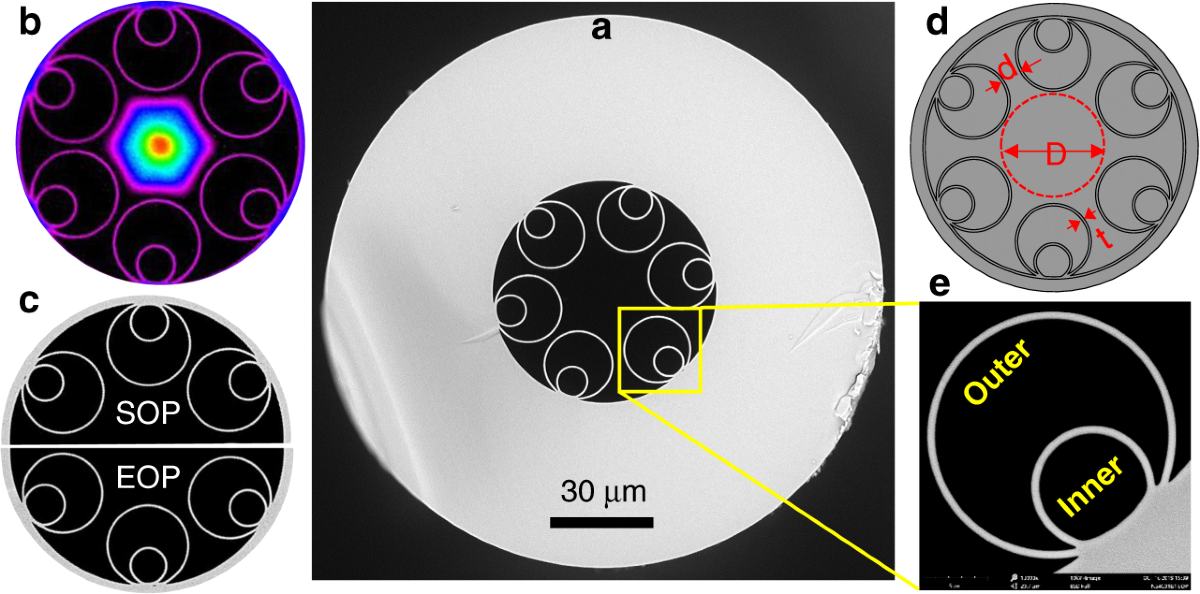

In numerous optical fiber production processes, precise dimension of fibre size is important for making certain regular efficiency and quality (optical fibre diameter analyser). Size analysers are innovative tools created to assess the physical dimensions of optical fibres with high precision. They utilize innovative optical and laser modern technologies to measure the diameter, ovality, and concentricity of the fibre, hence offering essential data for quality assurance

These analysers can operate in-line during the manufacturing process or as component of off-line screening Read Full Article protocols. In-line systems enable real-time tracking, allowing manufacturers to adjust specifications immediately, thus keeping optimal manufacturing problems. Off-line analysers, on the various other hand, give comprehensive assessments of sets, making certain that any kind of inconsistencies from specified resistances are identified and attended to.

Size analysers substantially add to the decrease of defects in optical fibres, boosting general product reliability. By continually determining key specifications, these modern technologies help with conformity with market standards and requirements. As the demand for high-performance optical fibers remains to increase, the duty of diameter analysers becomes increasingly important in accomplishing the wanted top quality and performance criteria in fiber optic systems.

Trick Attributes of Fibre Size Analysers

Although numerous designs of fibre size like it analysers exist, they typically share a number of vital attributes that enhance their functionality and reliability. One of the most substantial features is high-resolution dimension abilities, which make certain specific size analyses, crucial for keeping quality assurance in fiber manufacturing. Furthermore, lots of analysers include advanced optical sensing units designed to find minute variations in fibre diameter, therefore offering vital information for procedure optimization.

Another essential feature is real-time monitoring, permitting drivers to obtain instant feedback on fibre size throughout the production process (optical fibre diameter analyser). This capability facilitates quick modifications and reduces the likelihood of defects. Many analysers likewise come geared up with user-friendly user interfaces, enabling operators to conveniently navigate via information and settings outcomes

Furthermore, durable information storage and analysis capabilities are important for tracking historical efficiency patterns and ensuring compliance with industry standards. Some versions also supply connection options for assimilation right into existing manufacturing control systems, improving general operational effectiveness. Last but not least, compact and portable styles enable for versatile deployment within manufacturing environments, making sure that quality assurance procedures are smooth and effective. These functions jointly add to the efficacy of fibre size analysers in optimizing fibre optic efficiency.

Finest Practices for Fibre Optimization

First, routine calibration of optical fiber size analysers is vital. This makes certain precise dimensions and decreases possible discrepancies that might impact efficiency. Next, maintaining a clean workplace is vital; dust and pollutants can lead to signal deterioration.

Furthermore, it is very important to select fibres that satisfy details application requirements. This involves evaluating aspects such as depletion, data transfer, and environmental problems. Correct setup strategies must also be abided by, consisting of staying clear of sharp bends and too much stress, which can endanger fiber honesty.

In addition, using advanced monitoring systems can facilitate real-time efficiency evaluations, allowing timely identification of issues. Regular testing and upkeep need to be performed to make sure that fibers stay within optimal operational criteria.

Last but not least, training workers on the current fibre optimization technologies and methodologies will certainly boost their capability to execute effective approaches. By adhering to these finest practices, companies can dramatically enhance the performance and life-span of their optical fibre systems, ensuring reliable communication and data transfer.

Conclusion

In final thought, the integration of optical fibre diameter analyser innovation is vital for optimizing fiber optic performance. By guaranteeing precise measurements of fibre measurements, these analysers significantly improve signal top quality and decrease losses throughout information transmission.

Signal quality in optical fiber systems pivots dramatically on the diameter of the fibre.In lots of optical fiber manufacturing procedures, exact measurement of fibre diameter is necessary for ensuring consistent performance and high quality. As the need for high-performance optical fibers proceeds to climb, the role of diameter analysers ends up being significantly vital in accomplishing the wanted top quality and performance standards in fibre optic systems.

These attributes collectively contribute to the efficacy of fiber size analysers in maximizing fiber optic performance.

In verdict, the integration of optical fibre diameter analyser technology is important for making best use of fiber optic efficiency.